class ii division 2 hazardous locations

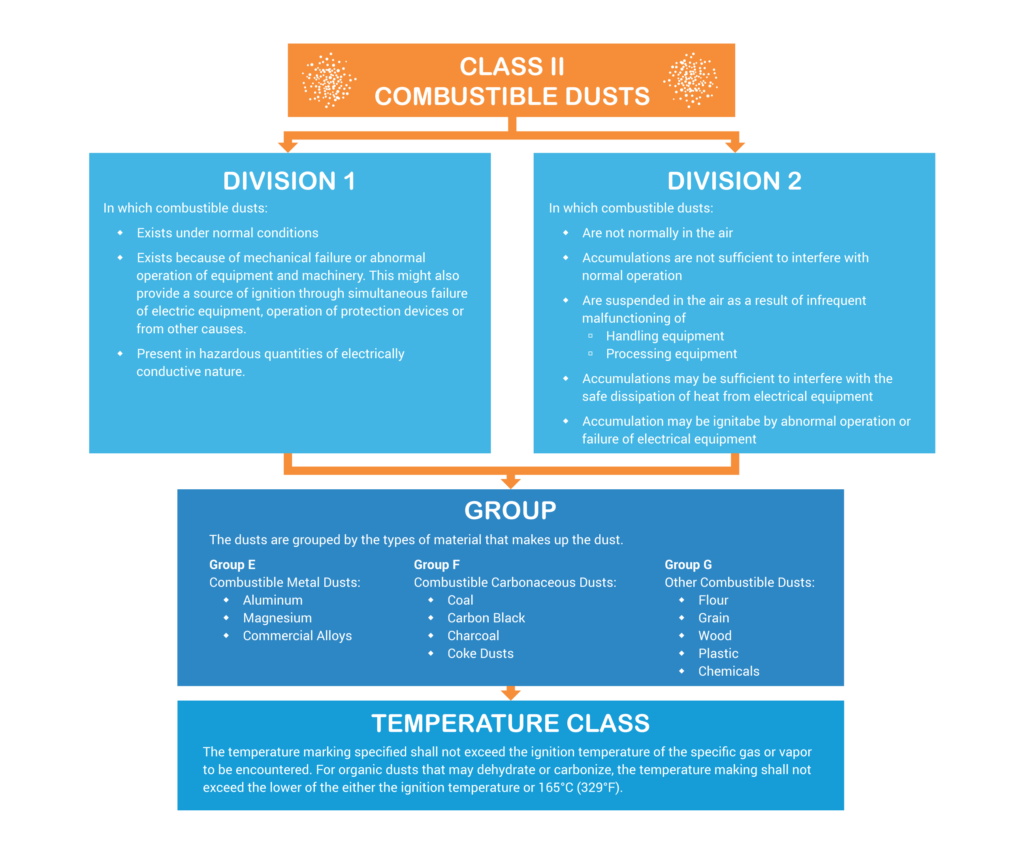

Articles 500 through 504 cover the requirements for electrical and electronic equipment and wiring for all voltages in Class I Divisions 1 and 2. In this animation we will focus on the Class-division system classification of dust explosive atmospheres specifically Class II Division 1.

Ul And C Ul Hazardous Areas Certification For North America Ul Solutions

Published 28 May 2020.

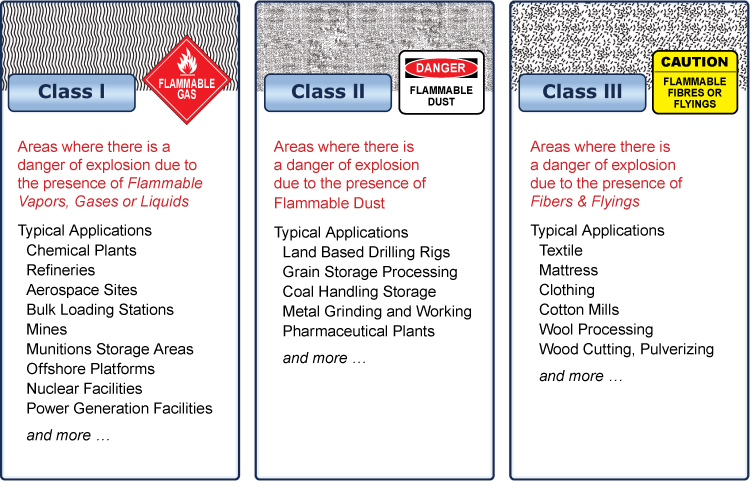

. Gain a better understanding of the definition of a Hazardous Location and area classification as well as the UL and C-UL Certification for North America. According To ISA-121201. Hazardous locations are areas where flammable liquids gases or vapors or combustible dusts exist in sufficient quantities to produce an explosion or fire.

Class II Divisions 1 and 2. But concentrations of hazardous substances are not high enough to be ignitable. Locations that are hazardous because of the presence of combustible dust.

In the Class-division system they are Class II Division 1 and Class II Division 2. Class II Division 2 Location. Combustible dust is not normally in the air in ignitable concentrations.

5001 Scope Articles 500 Through 504. Ad Your Total Compliance Resource For Labels. MICROSTROBE DIVISION 2 UL LISTED.

The Division 1 signifies that these hazardous gas or vapor air mixtures are present normally or for large periods of time. Just as in Class I Division 1 and 2 the subdivision of Class II into Divisions 1 and 2 identifies the likelihood that there will be an explosion hazard. The purpose of this standard is to provide minimum requirements for the design construction and marking of electrical equipment or parts of such equipment for use in Class I and Class II Division 2 and Class III Divisions 1 and 2 hazardous classified locations.

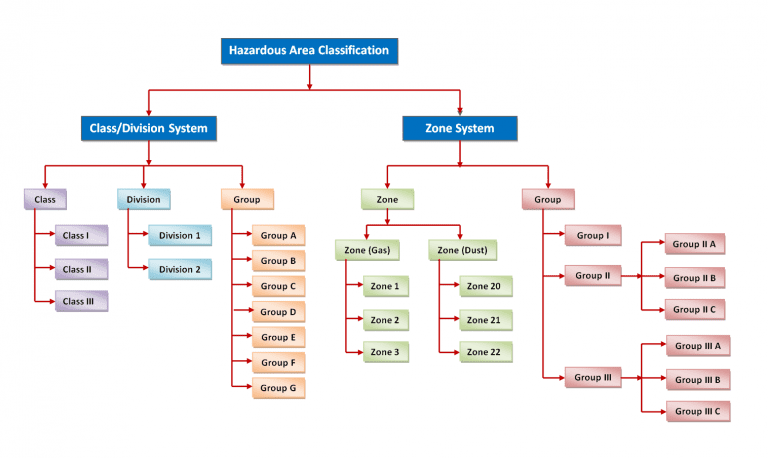

This equipment in normal operation. 1910307 g 1 Scope. There are two sets of Zones.

UN Hazmat Software More. Class I Division 2 or C1D2 for short products are electrical devices approved for use in a hazardous area or location in North America. And Class III Divisions 1 and 2 locations where fire or explosion hazards may exist due to flammable gases flammable liquid.

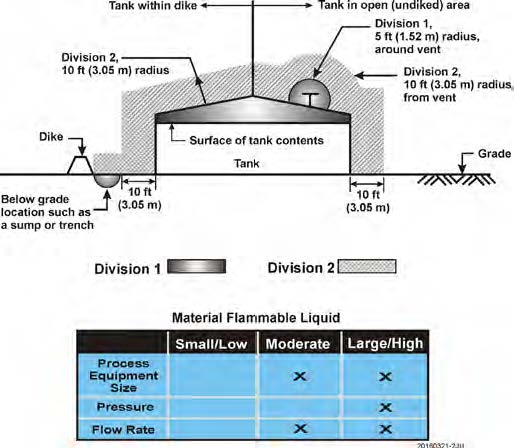

Zones 0 thru 2 are used for gases vapors and mists and Zones 20 thru 22 are used. The Zone system for classifying hazardous locations used in NFPA 70 NEC IEC 60079 and the Canadian Electrical Code indicates the level of probability that a flammable concentration of a hazardous substance may be present. The Model 490S-1280T and 490S-120T strobe light are UL listed for use in Class I IIDivision 2 hazardous locations.

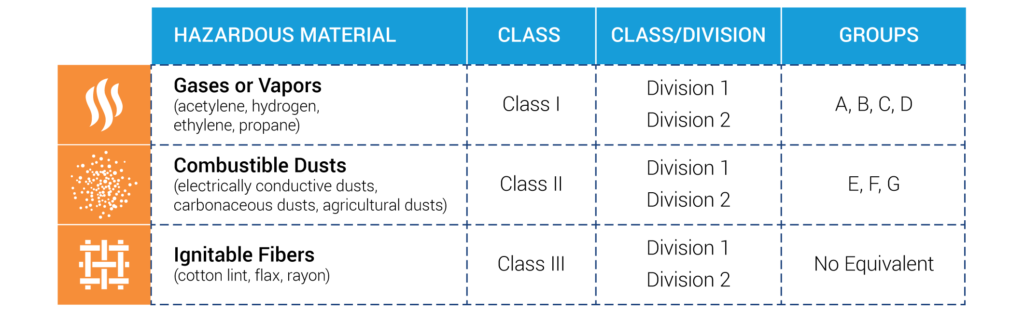

OSHA Publication 3073 defines a hazardous location as follows. These hazardous classified locations are assigned six designations as follows. Class 1 Hazardous Locations refer to facilities that deal with flammable gases vapors and liquids.

Dust is defined as a combustible material that must exist as a finely divided solid of 420 microns 0420 mm or less. Locations that are hazardous because of the presence of dust are defined in the Zone system as Zones 20 21 and 22. Division 2 specifies that flammable materials are handled processed or used at a location.

A Class 1 location means that the location has presence of explosive and or flammable mixtures of vapors or gases. Group Type of Hazardous Material. The salvage value of the rig after 5 more years of use is expected to be36000.

This applies to devices such as Flashlights Meter. In hazardous locations specially designed equipment and special installation techniques must be used to protect. These units have a Lexan lens and base polyurethane potted power supplies and are suitable for outdoor use in NEMA 4 locations They may be operated in any position and feature a 12 pipe.

An independent over-the-road OTR truck driverowner paid 68000 for a used tractor-trailer. These Class I II and III fixtures illuminate Division 2 hazardous locations where flammable gases or vapors combustible dusts andor ignitable fibers or flyings are normally confined or not present in ignitable concentrations. Class II Division 2 Groups F and G Explosion Proof Lights These fully-sealed durable explosion proof LED lights provide lighting within potentially dangerous spaces where ignitable vapors and gasses are present.

Atmosphere containing a flammable gas a flammable liquid produced vapor or a combustible liquid produced vapor mixed with air that may burn or explode having either a MESG Maximum Experimental Safe Gap 1 value less than or equal to 045 mm or a MIC Minimum Igniting. The operating cost is 050 per mile and the base mileage rate ie revenue is061 per mile. Their group ratings designate use in locations with specific types of gas vapor or dust.

Employers may use the zone classification system as an alternative to the division classification system for electric and electronic equipment and wiring for all voltage in Class I Zone 0 Zone 1 and Zone 2 hazardous classified locations where fire or explosion hazards may exist due to flammable gases vapors or. For definitions of these locations see 1926. They can be manufactured anywhere in the world but they need to be approved only by North American certifying agencies for use in Canada and the US.

1 - 1 of 1 Results. The fact that there is some combustible dust present does not mean a Class II hazardous location exists. Note that the dust must be present in sufficient quantities for a fire or explosion hazard to exist.

Class II Division 2 Groups F and G Remove All. Class I Division 1 Class I Division 2 Class II Division 1 Class II Division 2 Class III Division 1 Class III Division 2. Just as in Class I Division 1 and 2 the subdivision of Class II into Divisions 1 and 2 identifies the likelihood.

Each room section or area shall be considered individually in determining its classification.

Hazardous Area Classification Process Safety Fauske

Hazardous Area Classification The Instrument Guru

Explosion Proof Nema 4 Nema 4x Enclosures Class 1 Div 2 Enclosure Protection Nema Enclosures

The Definitive Guide To Hazardous Location Enclosures Isc Sales

Intrinsically Safe Vs Explosion Proof Equipment What S The Difference

Class I Hazardous Locations Ec M

Hazardous Location Classification

Hazardous Area Classification Process Safety Fauske

Hazardous Locations Guardian Telecom

The Definitive Guide To Hazardous Location Enclosures Isc Sales

5 Methods Of Protection Iaei Magazine

Overview Of Hazardous Areas Expo Technologies

Overview Of Hazardous Areas Expo Technologies

Comparison Of Iec Nec Area Classifications Inst Tools

Explosion Proof Nema 4 Nema 4x Enclosures Class 1 Div 2 Enclosure Protection Nema Enclosures

Code Q A Boundary Seals In Hazardous Locations Ec M

Hazardous Area Heaters For Nec 500 Nec 505 Hazardous Locations

Hazardous Area Heaters For Nec 500 Nec 505 Hazardous Locations

Corrosion Resistant Conduit And Fittings In Hazardous Locations Technical Documents Calbrite